Hengsheng Vibration Knife Cutting Machine: Big Visual Positioning+Automatic Edge Inspection Technolo

Release time:2025-04-21 16:24:04

Title: Hengsheng Vibration Knife Cutting Machine: Big Visual Positioning+Automatic Edge Inspection Technology, Innovating the New Era of High Efficiency Cutting for Printed Home Textiles

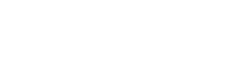

Introduction: Cutting pain points and intelligent transformation in the home textile industry

In the fiercely competitive home textile market, efficient and precise cutting of printed fabrics is the core link that determines production costs, quality, and delivery efficiency. The traditional cutting method relies on manual debugging or semi-automatic equipment,

Often faces problems such as large alignment deviation, high material waste, and difficulty in processing complex patterns. How to achieve "zero error edge inspection and one click intelligent cutting" has become a key demand for many home textile enterprises to move towards intelligent manufacturing.

Hengsheng vibration knife cutting machine redefines the standard of home textile cutting with its "big visual positioning automatic edge cutting" technology, solves industry pain points with intelligent solutions, and helps enterprises reduce costs and increase efficiency.

---

1、 Big visual positioning system: making cutting accuracy "visible"

The core innovation of Hengsheng vibrating knife cutting machine lies in the installation of a high-precision AI visual positioning system, which achieves millisecond level image recognition and positioning through industrial grade cameras and deep learning algorithms.

-Intelligent image analysis: The system automatically captures fabric texture, pattern edges, and positioning marks, generates cutting paths in real time, and eliminates manual measurement errors.

-Dynamic adaptive adjustment: In response to possible color differences, wrinkles, or deformations in printed fabrics, the visual system can dynamically calibrate the cutting position to ensure the edge neatness of complex patterns.

-Multi material compatibility: Whether it's silk, chiffon, or thick cotton fabric, the visual system can quickly adapt, greatly reducing the time for changing materials and adjusting machines.

Data evidence: Actual testing shows that after adopting large visual positioning technology, the cutting and alignment accuracy has been improved to ± 0.1mm, and the material utilization rate has been increased by more than 15%.

---

2、 Automatic edge cutting: from "manual edge cutting" to "machine intelligence"

In traditional cutting, workers need to repeatedly adjust the tool path to catch up with the edge of the fabric, which is time-consuming, labor-intensive, and prone to errors. Hengsheng's automatic edge cutting function completely subverts this process:

-One click start, intelligent edge tracking: After the device locks the fabric boundary through the visual system, the vibrating blade automatically cuts along the edge contour without manual intervention.

-Multi shape adaptive: Whether it is a straight line, curve or irregular pattern, the cutting angle and speed of the blade can be adjusted in real time to maintain smoothness and no burrs.

-Material saving mode: For small-sized fabrics, the system automatically plans the optimal layout path to reduce waste of scraps.

Scenario case: After a well-known home textile enterprise introduced Hengsheng equipment, its jacquard fabric cutting efficiency increased by 40%, daily production capacity exceeded 5000 meters, and edge material loss decreased by 20%.

---

3、 Application scenario: Efficient production covering the entire chain of home textiles

Hengsheng vibration knife cutting machine, with its flexibility and stability, adapts to the diverse needs of the home textile industry:

1. Printed fabric slitting: Quickly process large format floral fabrics and accurately segment order batches.

2. Quilted product cutting: For three-dimensional fillers such as the core and pillow core, achieve non indentation cutting.

3. Customized home textile processing: supports rapid prototyping and mass production of personalized pillows, curtains, and other small batch orders.

Customer Witness: A textile manufacturer in Zhejiang stated, "Hengsheng Equipment has directly transformed our design drawings into finished product cutting, reducing the sampling to mass production cycle by 50% and significantly improving customer satisfaction

---

Conclusion: Intelligent cutting opens up a new future of smart home textile manufacturing

In the home textile industry where efficiency is king and quality wins, Hengsheng vibration knife cutting machine takes big visual positioning and automatic edge inspection technology as its core, providing enterprises with a set of solutions from "precision cutting" to "intelligent production"

Integrated solution. Whether dealing with large-scale orders or personalized customization, Hengsheng equipment can make the cutting process a competitive advantage for enterprises rather than a cost burden.

EN

EN 中文

中文 عربي

عربي

Contact

Contact